Laser cutting machines are a critical tool in modern manufacturing. Whether you are a small business owner, a hobbyist, or part of a larger manufacturing operation, the cost of a laser cutting machine is critical, How much is a laser cutter?This blog aims to detail the factors that affect the price

In modern manufacturing and engineering, precision and efficiency are of paramount importance. Laser welding device stands out as the cornerstone of high-quality joining processes. With their precision, speed, and versatility, laser welding systems have changed the way we work with metals. This arti

Laser Cleaning Machines: Standing Out with Clear Advantages over Traditional Cleaning MachinesIn the field of industrial cleaning, the choice of cleaning technology has a crucial impact on production efficiency and product quality. Traditional cleaning machines have long occupied an important positi

The Versatile Applications and Outstanding Features of Laser Marking MachinesIn the modern manufacturing and industrial landscape, laser marking machines have emerged as indispensable tools, revolutionizing the way products are marked and identified. Their widespread use across various industries ca

The Multifaceted Uses of Laser Cutting MachinesIn today's rapidly evolving industrial landscape, laser cutting machines have emerged as a revolutionary tool, offering a wide range of benefits that make them indispensable across various sectors. From their environmental friendliness to their versatil

In the modern manufacturing industry, laser welding machines have emerged as a game - changing technology, offering a plethora of benefits over traditional welding methods. This blog post will explore the remarkable features of laser welding machines, with a focus on their simple operation, high eff

The Advantages of Fiber Laser Cutting Machines: Low Maintenance, Depreciation, and Material LossIn the modern manufacturing industry, fiber laser cutting machines have emerged as a game - changer. Their remarkable features not only improve production efficiency but also significantly reduce costs in

The High - Safety and User - Friendly Laser CutterIn the world of modern manufacturing and DIY projects, the laser cutter has emerged as a revolutionary tool. It offers precision and efficiency that traditional cutting methods can hardly match. But one of the most remarkable features of a laser cutt

The Welding Machine: Easy to Use and Widely ApplicableIn the world of metalworking and DIY projects, the welding machine is a powerful and versatile tool. Whether you are a professional welder or a hobbyist, understanding the simplicity of operation and wide range of applications of a welding machin

The Versatile Cutting Machine: Simple Usage and Wide ApplicationsIn the world of DIY projects, home renovations, and industrial manufacturing, the cutting machine is an indispensable tool. Its simplicity of use and wide range of applications make it a favorite among professionals and hobbyists alike

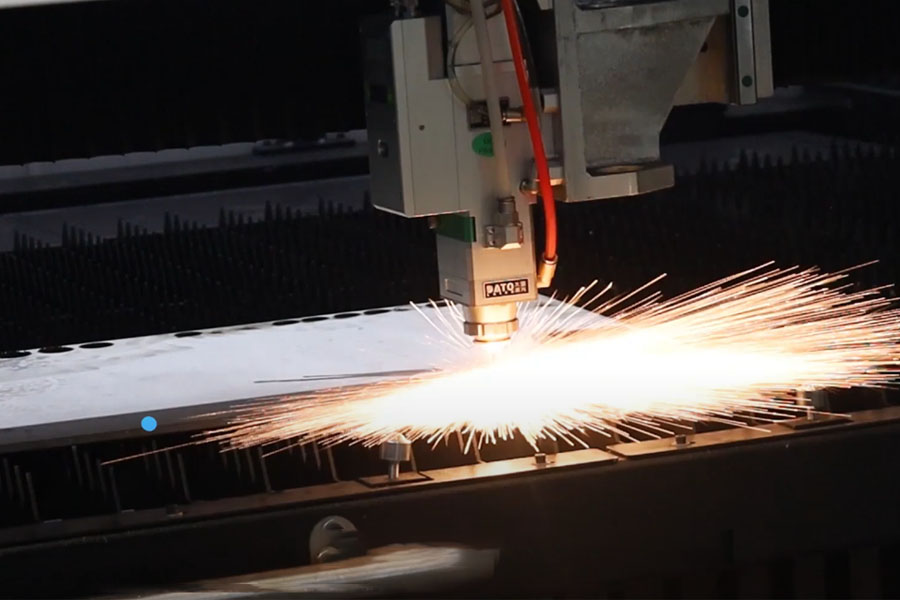

The Advantages and Features of Laser Cutting MachinesIn the modern manufacturing industry, laser cutting machines have emerged as a revolutionary tool, transforming the way materials are processed. But what exactly are laser cutting machines, and why are they so popular? Let's take a closer look.Wha

Understanding Laser Cleaning Machines: Technology and ApplicationsIn recent years, laser cleaning machines have been gaining popularity across various industries. From removing rust and paint in the automotive and aerospace sectors to cleaning historical artifacts in the cultural heritage field, the

In today's era of rapid technological development, various innovative devices are emerging continuously, bringing great convenience to our lives and production. The laser cleaning machine, as a new type of cleaning equipment, is gradually standing out in various fields. With its unique advantages, i

The Advantages and Features of Laser Engraving MachinesIn the modern manufacturing and creative industries, laser engraving machines have emerged as a revolutionary tool, offering a wide range of applications and remarkable advantages over traditional engraving methods. This blog post will delve int

Welding technology has significantly advanced, offering a range of techniques tailored to different manufacturing needs. Among these, laser welding and MIG welding stand out for their unique capabilities. This article explores each method's core principles, their distinct advantages, and their appli

When it comes to removing paint from wood surfaces, traditional methods like sanding, chemical stripping, or heat guns have long been the go-to options. Yet, these techniques can be labor-intensive, messy, and even harmful to the wood. Using a laser wood paint remover is a precise, efficient and env

Heavy rust accumulation is a common problem that affects a wide range of materials, particularly metals. Rust can quickly degrade the integrity and appearance of items. Selecting the right rust removal method is crucial to preserving the material's quality and ensuring its longevity. Laser rust remo

Laser cleaning has emerged as a cutting-edge solution for various industrial cleaning and surface preparation tasks. Known for its precision and efficiency, it is increasingly being adopted across industries. Yet, one of the key considerations for businesses is understanding the laser cleaning cost

Welding is an essential process in many industries, but it comes with significant risks. Understanding welding dangers is crucial for anyone involved in the process. These dangers can affect human health, the environment, and the materials being welded. This article will explore the risks associated

In the evolving world of welding technology, the portable hand held welder has emerged as a game-changer. Handheld laser welding machines stand out, providing the perfect blend of portability, efficiency, and precision. This article will explore why these portable handheld welders are indispensable.

Views: 70 Author: Site Editor Publish Time: 07-08-2024 Origin: Site

In manufacturing, precision is key. Laser cutting is a technology used across a wide range of industries. This article explores "laser cutting tolerances". This is critical to achieving the exact dimensions of manufactured parts. We will discuss the factors that influence tolerances, their specific ranges, and strategies to improve cutting accuracy.

Laser cutting tolerances refer to how accurately a laser cutting machine can cut a material to the specified dimensions. These tolerances are critical. They determine how well parts fit together in an assembly and function in their intended application.

There are a variety of factors that affect the accuracy of laser cutting. Understanding these factors helps to choose the right equipment and parameters.

Machine Accuracy: The mechanical accuracy of the laser cutting machine itself affects the cutting tolerance. This includes the stability of the laser beam, the accuracy of the guide mechanism, and the overall condition of the hardware.

Calibration: Regular calibration ensures that the machine operates within the specified tolerance range.

Material Type: Different materials behave differently under the laser beam. Due to different heat resistance and reflectivity, it will affect the cutting accuracy of the laser.

Thicker materials often pose challenges to laser cutting accuracy. Because thicker materials are more likely to accumulate heat and warp.

Power and Speed:The settings of laser power and cutting speed can greatly affect the cutting quality. Optimizing these parameters is critical to reducing deviations.

Laser Focus: The laser focus affects the concentration of the beam on the material. This affects the sharpness and accuracy of the cut.

Programming: The software used to control the laser cutting machine plays an important role in the accuracy with which the machine replicates the intended design.

Nesting Software: Software that optimizes the layout of the pattern to be cut. This reduces material waste and increases cutting efficiency. It indirectly affects tolerances by optimizing the cutting process.

Cutting width tolerance: For metal plates with a thickness of 1-20mm, the cutting width tolerance is usually within ±0.1mm. As the material thickness increases, the tolerance range may expand slightly. But it remains at a high level overall.

Edge verticality tolerance: In metal plate cutting, the edge verticality tolerance can generally be kept within ±0.5°. This range can ensure the straightness and accuracy of the cutting edge.

Surface roughness: Surface roughness is one of the important indicators for evaluating cutting quality. For metal plates, fiber laser cutting machines can usually achieve a cutting surface with a Ra value of less than 12.5μm. This meets the needs of most precision processing.

High precision: Fiber laser cutting machines have excellent beam quality and precise focusing capabilities. It is able to achieve high-precision cutting within a smaller tolerance range. In contrast, CO2 laser cutting machines often need help to achieve the same level of precision.

High efficiency: Fiber lasers have high electro-optical conversion efficiency and fast response speed. This feature enables it to maintain a high cutting speed and stability during processing. This not only improves production efficiency but also reduces energy consumption and costs.

Low maintenance cost: The structure of the fiber laser is relatively simple and durable, and the maintenance cost is low. CO2 lasers need regular gas replacement and complex maintenance work. This increases operating costs and maintenance difficulties.

Wide range of material adaptability: Fiber laser cutting machines are suitable for processing a variety of metals. Its excellent thermal management capabilities and precise cutting control enable it to maintain stable cutting quality.

Regular Calibration: Make sure you calibrate your laser cutting machine regularly. Keep it accurate throughout its life.

Routine Inspections: Perform routine maintenance inspections. Keep all mechanical parts in top condition and replace parts such as lenses and nozzles as needed.

Optimal Settings: Try different power settings and cutting speeds. To find the best combination for each material type and thickness.

Train Operators: Make sure your operators are well-trained. Learn how to adjust settings to get the best cutting performance and accuracy.

Update Software: Keep your cutting software updated to enjoy the latest algorithms and efficiency improvements.

Advanced Nesting Software: Use advanced nesting software to optimize material usage and reduce cutting. This can indirectly improve cutting accuracy by reducing machine load.

Stable Environment: Operate the machine in a controlled environment with consistent temperature and humidity. This avoids material deformation during cutting.

By understanding the above laser cutting tolerances, you can help your products meet stringent quality standards. Staying on top of the latest technology and mechanical capabilities is essential to maintaining a competitive edge. If you need more information, we would be happy to assist you with our expertise.

Laser cutting of metal sheets is a widely used cutting method.

Precision And Artistry: Exploring The World of Laser Cutting Patterns

What Are Laser Cutting Tolerances? What Are The Cutting Tolerances of Fiber Laser Cutting Machines?

"Metal Cutting Mastery: Insights into Modern Cutting Techniques And Their Applications"

How Accurate Is The Metal Cutting Laser? How To Maintain It?

Comparison of laser cutting machine accuracy, speed, effect and stability

How to improve the cutting accuracy of laser cutting machine?

Application of laser cutting machine in modern architectural aluminum curtain wall

How to solve the problem of machining accuracy error of laser cutting machine?